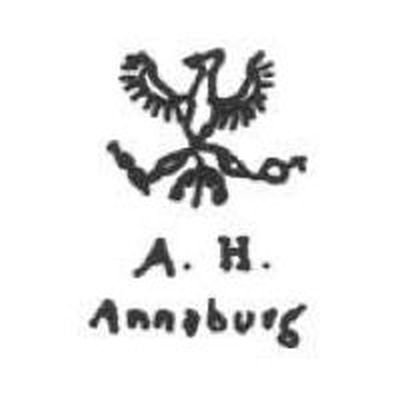

Image 0110-002-02-01

Used between 1883 and around 1923, eagle with scepter and orb above initials of Adolf Heckmann, found with or without "Annaburg".

The original factory, Annaburger Steingut-Manufaktur, was established in 1874. It employed ten workers and used a single kiln, but the business struggled due to a lack of knowledge and experience among those involved. Please note that no marks are known from this period.

The business was taken over by Adolf Heckmann, an experienced industrialist, in 1883, and it increased in size almost immediately. This allowed the factory to utilise four round kilns, each with a volume of 80 cubic metres, within a short period of time. Adolf Heckmann made plans early on to convert the firm into a corporation to ensure the continuation of the business after his retirement, as none of his three sons, Bernhard, Max and Willy Heckmann, were interested in taking over the factory as they had other plans.

At the time of the company's transformation, the factory was estimated to be worth 1 million Goldmark. It utilised twelve kilns and produced a wide range of stoneware items, art pottery and figurines. The company's premises covered a total area of 220,322 square metres, including housing and apartments for employees. While the Heckmann business became a corporation, his sons founded their own factory in 1897: a combined stoneware and glass factory named Steingutfabrik Sörnewitz AG in the small town of Sörnewitz near Meißen; Sörnewitz later became part of the town of Coswig.

Following the transformation, the main shareholders were Carl Untucht & Co. (explained further below), as well as the businessmen Gustav Müller and Hans Untucht, who both lived in Annaburg. For now, just bear in mind that we will be talking about three members of the Untucht family. Initially, everything continued as normal; however, the effects of the struggling German economy from around 1899 to 1901 caused some difficulties. Minor changes to the product range, including presenting various household goods such as washbasins and milk pots with Zwiebelmuster (Blue Onion) decorations, helped. This was followed by introducing airbrush and stencil decorations after Emil Sauerbrei joined the Annaburg company in 1903, bringing with him the knowledge he had acquired while working for Rosenthal.

At that time, the factory employed up to 500 people, and setbacks such as the fire that nearly destroyed the main building on 1905-01-24 could not stop business. By 1906, the factory had around 600 employees and, in 1909, a modern tunnel kiln for producing high-quality stoneware was installed. However, a few years later, the situation had changed, and the corporation was one of many looking for new markets and employees to boost business. One of these people was Friedrich Carl Untucht, who later joined the company as a director.

Friedrich Carl Untucht, a businessman, was born on 1870-05-10 in Magdeburg. He was the only child of Carl Untucht (*1835, †1906), the owner of the spirit refinery business Carl Untucht & Co., which was founded in 1876 and had its main office in Berlin. Friedrich learned the trade by working for his father, joining the company as a partner shortly before his father's death in 1906. Seeking a challenge, the young businessman started to expand the business, and by 1913, all spirits produced in and around Magdeburg came from the Carl Untucht & Co. facility. His greatest achievement was the takeover of the Dschenfzig'schen Melasse- & Spiritusbrennerei, which secured Untucht a monopolistic position in the market.

However, he would not have been so successful if he had not been interested in politics and its surrounding issues. He was therefore one of the first to realise the imminent changes. Some representatives had been discussing a new law that would result in total state control of spirits: the so-called Branntweinmonopolgesetz. In order to secure his income and the future of his business, shortly after his father died, he bought the area next to the family business and started running a small earthenware facility which mainly produced bottles for holding various spirits and beer. Untucht was also a board member of Bodenstein AG Magdeburg, a brewery owned by Theodor Franz Julius Bodenstein. Given his previous success and experience with earthenware, Untucht was the obvious choice to become director of the Annaburger Steingutfabrik.

As director, Untucht instantly restructured parts of the business, rapidly increasing quality and output and leading the company to new heights. After a very short time, he acquired a majority of shares and took over the business in 1919/1920. He incorporated his former earthenware facility in Magdeburg into the corporation. This helped the company to cope with the rising demand, as it could now produce mainly for export. There are no further records of the business's growth, and the only known figures are that the number of employees dropped to around 300 in 1918. By 1925, this figure had fallen further to 230, but then rose again to around 600 by 1928 due to the economic upturn. This figure fell again to 270 in 1934 due to the effects of the Great Depression.

Over time, the product range at the Annaburg and Magdeburg facilities increased drastically to include lamp bases, vases, planters, washing sets, kitchen utensils, basic tableware, classy tableware, and coffee and tea sets. All items were decorated in the on-site decoration studios using various glaze and underglaze decorating techniques, such as airbrushing, stencilling and traditional hand painting.

As a seasoned businessman, Untucht had always been keenly observant, including in political matters, and he recognised the danger posed by the National Socialist party to Germany very early on. His experience and knowledge told him that a war would have a devastating impact on the German economy, despite what Nazi propaganda told people. However, he did not live to see the outbreak of World War II. Friedrich Carl Untucht died at the age of 69 in Braunlage, a small town in Saxony-Anhalt, and the company remained under the management of his fellow directors, Hans Untucht and Schäfer, who guided the factory through the difficult war years. Although the factory was damaged during the war and experienced some minor periods of closure due to the collapsing economy shortly before the end of the war, it survived the war. However, the stress proved too much for Hans Untucht, with dire consequences: he committed suicide on 1945-07-09.

Especially the pre-war employees Böhme, Heinrich, Kampfhenkel, Pfund and Sauerbrei were heavily involved in the rebuilding process that followed the end of the war, a fact later stylized into a typical socialistic workers' hero propaganda story. Truth was however that not the named group of five in some 'glorious socialistic effort' restarted work all on their own, they were only five of the remaining 40 workers in Annaburg. While the first months were spent clearing up, repairing and partially rebuilding the factory, the main problems remained the supply with urgently needed chemicals and of course coal for firing the small round kilns. By 1946 the factory had around 150 employees again and that count passed the mark of 200 people in 1947 while it even more increased to 350 in 1948 after the large tunnel kiln could finally be taken into operation again.

During the first post-war years, the factory produced a wide variety of urgently needed household items. After the foundation of the GDR in October 1949, the company was nationalised and continued to trade mainly in the same products. It grew successfully, finally employing 456 people by 1956. One reason why people fail to find any marks from this period is that the factory mainly operated as a subsidiary of VEB Colditz, meaning the known marks were either dropped completely or the Annaburg name was integrated into others. This resulted in unusual marks, such as the CP Annaburg Sitolan mark, which was introduced in 1969.

Sintolan itself, incidentally, was a new type of improved fine stoneware (or "half-porcelain", as it was then known), invented at the Colditz plant, which successfully combined the positive features of stoneware and porcelain. However, producing this new material required a modern tunnel kiln. After this had been installed, the old tunnel kiln was upgraded to use gas, enabling the parallel production of classical stoneware and Sintolan items with up to 550 employees by 1988.

Next to the commonly used name VEB Annaburg Porzellan, the official name of the factory itself changed fairly frequently over time, mostly based on internal changes to the combine structure. To avoid confusing people by adding each name as a separate section header, the different names should at least be mentioned once:

1946: Annaburger Steingutfabrik

1947: Industrie-Werk Sachsen, Annaburger Steingutwerk

1948: VVB der Bau- und Baustoffindustrie Sachsen-Anhalt, Annaburger Steingutfabrik, Annaburg / Kreis Torgau

1949: VVB (G) Baustoffe Sachsen Anhalt, Annaburger Steingutfabrik, Kreis Torgau

1950: VVB Keramik, Annaburger Steingutfabrik, Annaburg / Kreis Torgau

1953: VEB Steingutwerk Annaburg / Kreis Jessen

1970: VEB Porzellankombinat Colditz, Werk Annaburg

1973: VEB Sintolanwerk Annaburg, Betrieb des VEB Porzellankombinat Colditz

1980: VEB Vereinigte Porzellanwerke Colditz, Werk Annaburg

By 1989, the factory was producing not only for the local market, but also for a total of 28 different countries. Backing from foreign customers, who filled the order books, helped the factory survive the next few years. Following the collapse of the German Democratic Republic, VEB Annaburg Porzellan was incorporated into the Treuhandanstalt programme, which had been set up by the West German government to support and restore former East German companies through reprivatisation. As part of this programme, factories were completely overhauled in an effort to modernise, optimise and restructure existing facilities, thus bringing them up to the same levels of effectiveness and productivity as their West German counterparts. This could often only be achieved through significant job cuts, and during this period, the Annaburg factory lost nearly all of its former workers, with over 500 being made redundant. The factory was also renamed Annaburg Porzellan GmbH at this time.

The Treuhandanstalt had decided to close the factory on 1991-12-31, as no investor could be found. However, shortly before this deadline, CERAPLAN GmbH in Bavaria expressed an interest. Meetings were held between the Treuhandanstalt, CERAPLAN and the Annaburg factory, and on 1992-07-01, the privatised company was finally released from the Treuhandanstalt and taken over by CERAPLAN. Modernisation, redevelopment and new organisational structures enabled the new owners to lead the factory into a new period of economic growth. The company adapted to the demands of local and international markets, producing not only tableware and hotel porcelain, but also a range of special bathroom accessories and gifts.

A café, a museum, and a painting school were also opened on the premises, and the factory soon employed 80 people again. It was the only remaining porcelain tableware factory in the Saxony-Anhalt region. Another milestone in the company's history was reached with the development of a new material for hotel and restaurant ware: an impressive in-house development called CORDOFLAM, which was registered and introduced in December 2010. This "more-than-ovenproof" material far exceeds normal requirements and can even withstand rapid temperature changes of over 400°C. This is demonstrated by immersing a preheated item with such a core temperature in a basin of ice water without causing any damage to the item or glaze.

However, the initial euphoria could not withstand reality for long. As cheap imports increased, forcing German factories to lose more and more ground, one factory after the other was eventually forced to give up. On 2015-05-13, Managing Director Peter Ploss filed for bankruptcy at the court in Dessau-Roßlau, and Annaburg Porzellan officially closed in August 2015.

In addition to the Annaburg items sold directly by the factory, there are also items that it made for other companies. For example, one of the container sets made for the US importer GMT & Bro.; one of these container sets shows the Annaburg eagle mark above "397" over "Delft" in addition to the GMT mark with item code "2851".

Please note that various decorations are known by both name and number, for example "Renate" (№·342), "Holland" (№·355), "Delft" (№·397), "Netze" (№·434), "Cöln" (№·446), "Thorn" (№·508), "Cardinal" (№·515), "Freya" (№·533), "Torgau" (№·542) or "Neisse" (№·543). But these are by no means all of them. One series produced by the Annaburg factory was known only as "Marlene", the name being claimed to refer to both the form and the decoration.

My marks table is still missing at least two marks: the first is an eagle above the initials "A St A", and the second is an eagle above the ligated initials "A S AG". Both marks were in use between 1895 and around 1923.

Image 0110-002-02-01

Used between 1883 and around 1923, eagle with scepter and orb above initials of Adolf Heckmann, found with or without "Annaburg".

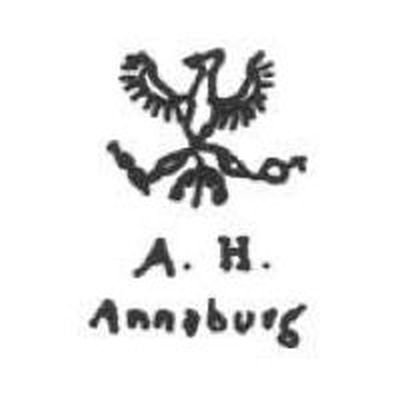

Image 0110-002-02-02

Used between 1883 and around 1923, same as before, example with "Annaburg".

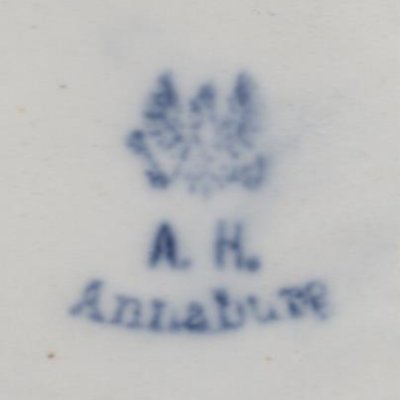

Image 0110-002-02-03

Used between 1883 and around 1923, another example with "Annaburg".

(Picture: June Jefferson)

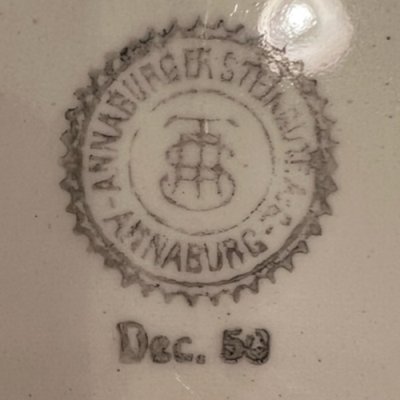

Image 0110-002-03-01

Used between 1897 and 1917, reads "Annaburger Steingutf.-AG".

(Picture: Christine Sundberg)

Image 0110-002-03-02

Used between 1915 and 1925, here with "Holland" and "355".

Image 0110-002-03-03

Used between 1915 and 1925, here with "Netze" and "434".

Image 0110-002-03-04

Used between 1915 and 1925, here with "Cardinal" and "515".

Image 0110-002-03-05

Used between 1915 and 1925, here with "Torgau" and "542".

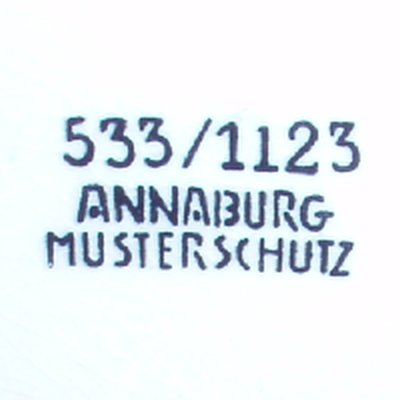

Image 0110-002-03-06

Used around 1920, decoration number "533" next to the mold number, "1123".

(Picture: David Lofton)

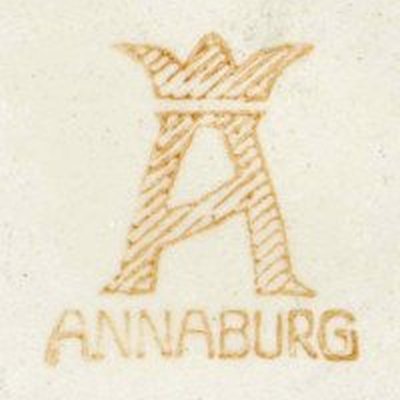

Image 0110-002-03-07

Used 1920 to 1930 (some say 1945), an impressed version with "Annaburg".

Image 0110-002-03-08

Used 1920 to 1930 (some say 1945), with a handwritten addition.

Image 0110-002-03-09

Used 1920 to 1930 (some say 1945), here with the "454" decoration code.

Image 0110-002-03-10

Used 1920 to 1930 (some say 1945), here with the "1532" item code.

Image 0110-002-03-11

Used 1920 to 1930 (some say 1945), here just with "Dec. 515" noting the "Cardinal" decoration.

Image 0110-002-03-12

Used 1920 to 1930 (some say 1945), here with "Dec. Nürnberg" noting the decoration.

Image 0110-002-03-13

Used 1920 to 1930 (some say 1945), example showing that even smudged marks passed quality control.

Image 0110-002-03-14

Used 1920 to 1930 (some say 1945), here on a "Gerda" item from the "Kunst-Keramik" line.

Image 0110-002-03-15

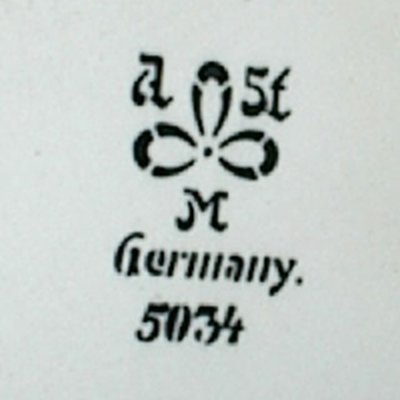

Used between 1922 and 1945, the three-leafed floral .

Image 0110-002-03-16

Used between 1922 and 1945 at the Annaburger Steingutfabrik subsidiary in Magdeburg used after 1922 ("5034" is the item code).

Image 0110-002-03-17

Used around 1930 at the Annaburger Steingutfabrik subsidiary in Magdeburg for the Carl Untucht spirit refinery.

Image 0110-002-04-01

Used between 1948 and 1952, the "VVB Annaburg" mark.

(Picture by Carsten Mehl)

Image 0110-002-04-02

Used around 1953, early form of the "VEB Annaburg" mark.

Image 0110-002-04-03

Used between 1957 and 1969, the "VEB Annaburg" mark.

Image 0110-002-04-04

Used between 1973 and 1990, mark used in Annaburg on "Sintolan" items made for the VEB Colditz.

Image 0110-002-04-05

Used between 1973 and 1990, same as before but with oval "Germany (East)" sticker.

Image 0110-002-05-01

Used since 1990.

Image 0110-002-05-01

Used since 1992.

Image 0110-002-05-02

Used since 1992, with "Easy Function" addition.

Image 0110-002-05-03

Used since 1992, mostly used on backs of limited editions.

Image 0110-002-05-04

Used since 2010, the "Cordoflam" product logo.

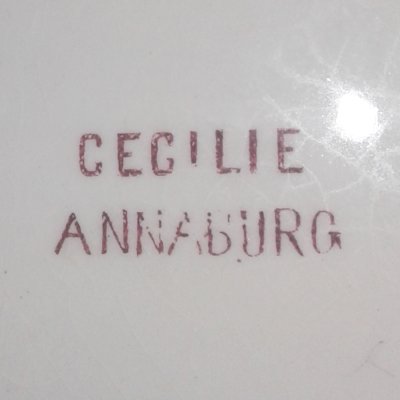

Image 0110-002-00-01

Period of use unknown.

(Picture: Ivan Golksi)

Image 0110-002-00-02

Period of use unknown.

(Picture: Jim Fetzer)

© 2004-2026 C.S.Marshall, all rights reserved